Controlled‑Environment Agriculture (CEA) combines hydroponics, precise environmental automation, and optimized lighting to maximize yield, quality, and resource efficiency. This guide translates key scientific principles—VPD, PAR/PPFD, root‑zone oxygenation—into practical decisions for commercial growers, researchers, and advanced hobbyists. Optimizing plant physiology for maximized yield and efficiency The modern greenhouse has evolved from a passive solar structure for season extension into a dynamic, data‑driven bioreactor. Precision control over environmental variables is now the primary lever for influencing plant phenotype, accelerating growth cycles, and maximizing resource‑use efficiency. This article provides a technical analysis of key advancements in controlled‑environment agriculture systems, focusing on the scientific principles that underpin their effectiveness. A fundamental choice in CEA design is between substrate‑based culture (e.g., rockwool, coco coir) and authentic liquid‑based soilless culture, such as Nutrient Film Technique (NFT) or Deep Water Culture (DWC). The efficacy of NFT hinges on fluid dynamics and root‑zone gas exchange. A laminar film of nutrient solution is maintained over bare roots, providing continuous access to water, macro/micronutrients, and—critically—dissolved oxygen. High oxygen availability in the rhizosphere prevents hypoxic stress that diminishes root respiration and active uptake of ions such as phosphorus (P) and potassium (K). This makes NFT ideal for low‑density, fast‑growing leafy greens and herbs with relatively shallow root systems. For research and commercial applications that demand repeatability, our engineered high‑performance NFT and recirculating systems are designed for optimal flow rates, minimal channel deformation, and sanitary operation to reduce pathogen pressure. The core of modern CEA is maintaining environmental variables within narrow, crop-specific setpoints via integrated climate control systems and sensor networks. While relative humidity (RH) is a familiar metric, vapor pressure deficit (VPD) is the true driver of transpiration. Defined as the difference between the moisture the air can hold at saturation and the moisture it currently has, VPD (kPa) directly modulates stomatal aperture and hence mass flow of water and nutrients. Incorrect VPD can trigger edema, tip burn, and stunted growth. Modern controllers compute VPD from temperature and RH using psychrometric equations and then orchestrate ventilation, heating, dehumidification, and misting to hit target setpoints. Consistency yields consistency. Our automated environmental control integrations dynamically coordinate fans, vents, heat, and misting to maintain target VPD for your crop and stage. Light provides energy for photosynthesis and serves as a signal for morphological changes (photomorphogenesis). PAR (Photosynthetically Active Radiation): spectral band 400–700 nm used in photosynthesis. PPFD (Photosynthetic Photon Flux Density): μmol/m²/s striking the canopy per second—your critical intensity metric. Spectral cues influence architecture: blue light (400–500 nm) promotes stomatal opening and compact growth, while red light (600–700 nm) is highly efficient for photosynthesis. Far-red light (700–800 nm), via the phytochrome system, drives shade avoidance, internode elongation, and can influence flowering timing. We design lighting layouts to specified PPFD/DLI and crop outcomes. Inquire about spectrum mixes for greens versus fruiting crops and how to integrate them with daylight dimming. Closed‑loop recirculating hydroponic systems reduce evapotranspirative loss and can achieve water‑use efficiencies above 90% compared to open‑field production. Precision monitoring of EC and pH allows targeted adjustments that minimize fertilizer runoff and mitigate nitrogen/phosphorus pollution. Integrate dosing control, EC/pH monitoring, and alarms to protect crop quality and reduce input costs. Discover our commercial growing systems, designed for auditability and scalability. Peak productivity and efficiency emerge from the integration of soilless culture, environmental control, and light management—each tailored to the specific needs of crop physiology and business objectives. Ready to formalize your design? We’ll map crop requirements to hydroponic architecture, environmental controls, and lighting to deliver measurable outcomes. PAR: 400–700 nm photosynthetically active spectrum. PPFD: photon flux density (μmol/m²/s) at canopy—use to set lighting intensity. Air’s drying power (kPa) derived from temperature and RH—the actionable control variable for transpiration and nutrient mass flow. EC: electrical conductivity proxy for nutrient concentration. pH: acidity/alkalinity influencing nutrient availability and uptake. Soilless method using a thin moving film of nutrient solution over exposed roots to maximize oxygenation and controlled feeding.

An Analysis of Advanced Controlled‑Environment Agriculture (CEA) Systems

The Shift from Simple Protection to Precision CEA

System Architecture: NFT channels maintain vs. True Soilless Cultivation (Commercial Hydroponic Growing Systems)

Scientific Deep Dive: Nutrient Film Technique (NFT) Hydraulics

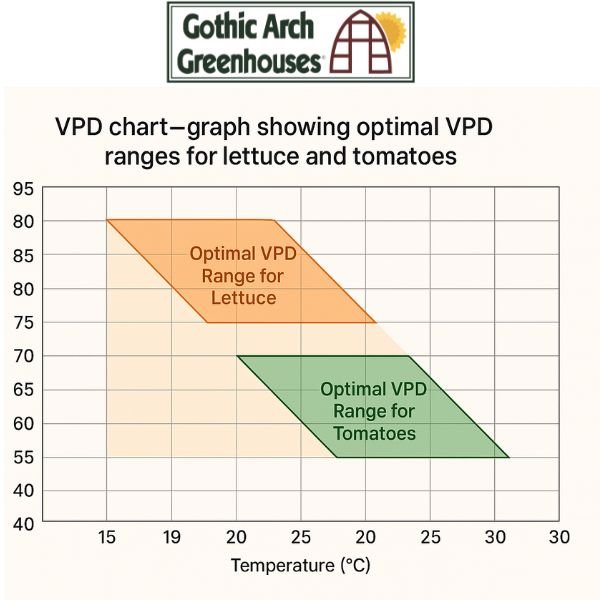

Automation & Environmental Control: Managing Vapor Pressure Deficit (VPD) in Greenhouses

Scientific Deep Dive: Why VPD Outperforms RH

“VPD—not RH—is the actionable control variable for consistent transpiration and nutrient flow.”

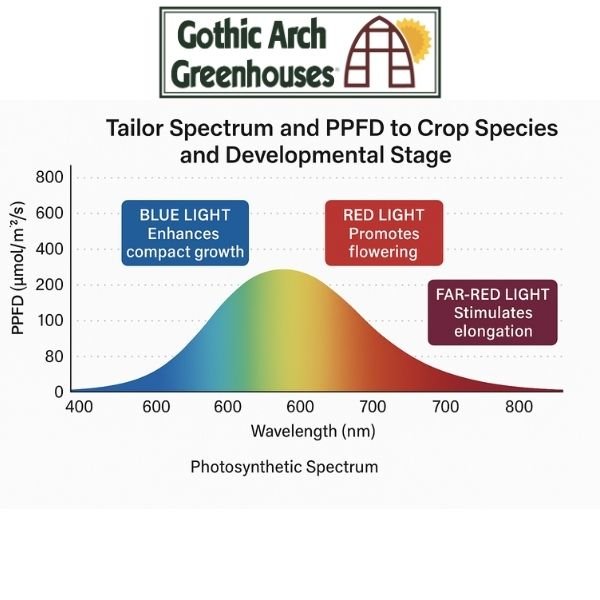

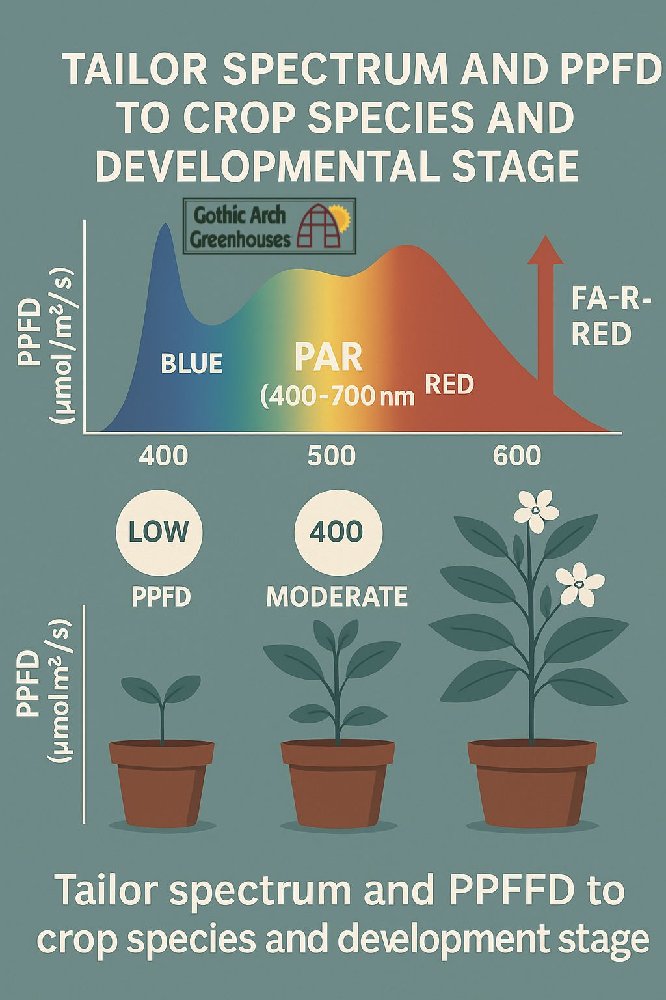

Greenhouse Lighting Optimization: PAR, PPFD & Photomorphogenesis

Resource Use Efficiency: Water, Nutrients & Energy

Putting It Together: Integrated Controlled‑Environment Agriculture Systems

Glossary (Quick Reference)

PAR / PPFD

VPD (Vapor Pressure Deficit)

EC / pH

NFT (Nutrient Film Technique)

Engineered for Precision

Practical takeaways

Integrated Control Solutions

Practical takeaways

Lighting Plans That Pay Back

Practical takeaways

From Data to Decisions

Practical takeaways

Specify Your System